MachinePix Weekly #14: Carl Bass, former CEO of Autodesk

Carl Bass, former CEO of Autodesk, on building boats, arguing with Steve Jobs, and endless side projects. This week's most popular post was "crane-ception". ⚙️

This week I sit down with Carl Bass—boat-builder, furniture maker, and the former CEO of Autodesk—to talk about the history of engineering software and his countless side projects.

The most popular post last week was a crane lifting a crane lifting a crane in one very excessive product demo. As always, the entire week’s breakdown is below the interview.

I’m always looking for interesting people to interview, have anyone in mind?

—Kane

Interview with Carl Bass

Before you started your first company, you chose to build boats and sculpt for five years. What was that like?

I wasn’t actually ready to go to college. I was 17, I had no reason to go, so I dropped out sophomore year and I wandered around. I did some construction work in North Carolina and South Dakota. Helped build some houses on the Sioux reservation. Ended up in Seattle, where I made furniture and some boats. Did that for a while and went back to Maine, where I built another boat. My favorite time was in Seattle. During the winter I would build things, during the summer I guided rafts.

Flying Moose, the company you founded, became an instrumental part of mechanical engineering over the past few decades via Ithaca Software and Autodesk. What originally compelled you to start the company? What were you trying to solve?

This was the early 80s. When I went back to school, computers and the very beginnings of PCs were starting to take place. My buddy and I lived in a college town, and we were just trying to figure out what all this cool computer stuff was. We helped a bunch of the faculty researchers at Cornell, where we were consulting and helping them commercialize research for about five years. It’s very different what researchers and grad students provide and what was commercializable: we were that bridge.

Our specialty was 3D graphics, and this was the beginning of UIs and interactive computers. I remember we helped Johnson & Johnson build software for shaping implants correctly. We did some things with earthquake prediction, remote sensing—it was a fascinating mix. We were doing computation and 3D graphics for all of it. We realized there was a common thread to what everyone was doing, and turned it into a piece of software. That became Flying Moose.

Where did the name Flying Moose come from?

I wish there was a better story, but at some point we went through this crazy process where we needed a corporate name, and we were behind on paperwork, and this was before the internet. We had to choose one that we knew no one else had. The full name was Flying Moose Graphics and Systems Ltd.

We had a customer call us up and tell us they really wanted to buy our software, but couldn't send a company named Flying Moose through the purchasing department. It was Boeing. GE and Dupont all hated it too. That’s why we changed it to Ithaca Software.

That sounds like a dumb reason to change a cool name.

Yes it was.

What are some of your favorite stories from your time in industry that you’re allowed to share?

The most fun I had at Autodesk was touring with our customers. When you make tools for people, especially creatives, they’re willing to share their deep secrets, because they look at you as someone that can help them solve the problem.

All the places I would visit, the engineers would take me aside and show me what the new secret thing they were working on and what they wanted to do in software. BMW, Boeing, Norman Foster, Hadid, Gheary… they would all show me their new products and tell me what they really wanted to do. We were talking to James Cameron when he was thinking about making Avatar, and he was really excited to talk about motion capture and what he wanted to do with it.

I did have a conversation one day with Steve Jobs. He had an affection for architecture. Autodesk architectural software didn’t run on Mac. When he was building something and his architect had to use a Windows computer, he would call and yell at me. This happened all the time. I remember when he was at Pixar, he preemptively called me to yell at me about something. At some point he said “Carl, listen to me, I’m your best customer”. I stopped him—I said “hold on, in what world are you my best customer? You’re cheap as hell, and you’re incredibly technically demanding. And you never give us public credit for anything!” As those who knew Steve well, it didn’t change his opinion at all. In his mind he continued to be our best customer. That said, in some ways he was great. He really pushed our software’s capabilities.

Those are the famous names, but behind every product there are thousands of designers doing really awesome work—and I loved meeting them and learning what they wanted. There was always a kind of secret excitement behind it, I always thought that was really cool.

What are some misconceptions about engineering software that you often see?

There are things that engineering software does incredibly well. It can go very deep and there are many hard problems that have been solved. What I think that people miss is that there are still huge amounts of unsolved problems. A common example would be any solid modeling software: it just asks you to start drawing, even before you know if you have an engineered solution. If you’re building a mechanism: should you use gears, pulleys and belts, chain sprockets? The modeling software doesn’t ask or care. These solutions happen outside of the engineering software. Paper. Excel. Matlab, or something. And it’s still not connected!

On the other end of the process, engineering software is not well-connected to fabrication. There’s a huge chasm between having a theoretically perfect model you have, and then you having to make it. The world is filled with imperfections. Your tools, your materials: everything is imperfect but it’s not in your model. That gap is slowly being filled, but there’s still a big gap.

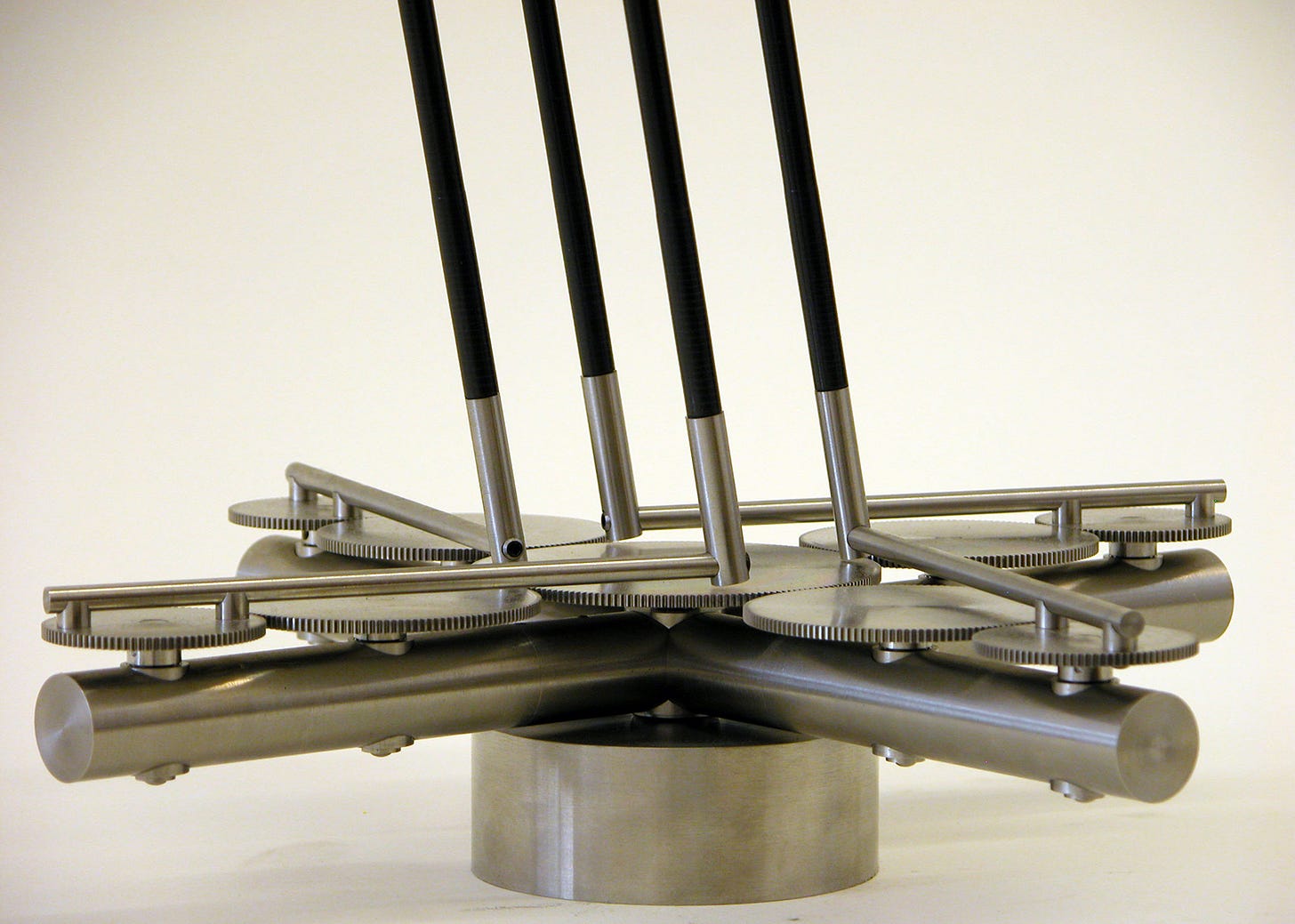

For years people referred to it as CAD (computer aided design) but the computer does no “aiding!” It’s much more computer “recorded” design. As we go forward with technologies like generative design, we’ll see more “aiding”. My chair project is generatively designed. The brackets in my canoe project are generatively designed. They are the most over-designed part in a wood canoe.

I’ve seen you build your own 1950’s electric truck and canoes on your Twitter. What are some of your favorite personal projects?

I love the process of making. I’m less affectionate about the things afterwards. One of my favorite projects I turned a MIG welder into a metal 3D printer. I love that one because it was cheap to do, no one had done it, and I can make really cool parts with it. This winter I need to get back to that and see what else I can do.

Any side projects you’re working on right now?

The truck we built, I drove it around for a couple months. I just stripped it down for powder coating. I’ll get to drive it again next week. I just wanted to buy an electric car but couldn't find a single one I liked. So I said to myself “I think we can build one of these.” It’s totally fun. You’re sitting at the stoplight, people think you’ll be slow. These old trucks had like 95 HP, this one has 350 HP

Building it from the ground up is just a hoot. There are a lot of interesting little problems. There are these old analog gauges, I’ve been trying to turn all the electric motor controller information to analog readouts.

What inspires / how do you decide what projects you want to work on?

There’s not much of a process. One of the luxuries I have these days is that me and the guys I work with, we spend a lot of time going down the rabbit hole of anything interesting at my shop. When we find a loose thread, we just pull on it. Right now we’re building a bunch of mechanisms. I saw sculptures by Anne Lilly I really liked, I couldn't figure out how they all worked. So right now we’re fabricating one inspired by her to see how they actually work. That will be a week diversion. Something to do while the truck chassis is being powdered-coated.

I spent a week not that long ago trying to automate the design of things with threads in CAD software. I had to learn the history, design parameters, processes… “make threads” sounds like it’s a solved problem, but it’s ridiculously painful. I just thought “this has got to be easier”.

What’s your favorite simple (or not so simple) tool or hack that you think is under-appreciated?

I got a couple of these. I was talking to Kevin Kelly, and he made me think of my favorite tools. My favorite hack is actually, when you get pistachios, you know when you get some that are hard to open? You can use half a shell from one pistachio to open the really hard to open ones.

I’ve become very fond of tools that use decimal inches. There are a whole set of tools and measures in my shop with decimal inches. Unfortunately we don’t have the metric system, and using fractional inches really sucks. With the truck build, all the old parts are all Imperial. The new parts I’m installing are all metric. It’s half and half, a real pain in the ass. My American CNC machines have Imperial parts, but the tool holders are metric. I hate it. Decimal inches helps a little.

The Week in Review

This week’s most popular post! Liebherr announced three new cranes during its 2012 Customer Day at its Ehingen factory with this wild demo.

This is actually the second time an Ampelmann motion compensated gangway has made it on to @machinepix. The first time was an inter-ship transfer.

Wolfgang’s YouTube channel is quite something.

EV Nautilus has an amazing YouTube channel if you’re a marine biology nerd like me. My favorite video is the crew making fun of a stubby squid at 900m depth.

Postscript

Speaking of generative design, our portfolio company nTopology provided the engineering software Bionic Pets used to generatively design high-performance dog prostheses 😍

If you enjoyed this newsletter, forward it to friends (or interesting enemies). I am always looking to connect with interesting people and learn about interesting machines—reach out!

—Kane