MachinePix Weekly #3: Brian Ignaut, lead solar array designer at SpaceX

SpaceX lead solar array designer talks about origami and woodworking. Also, a questionable haircut robot and a strange plane.

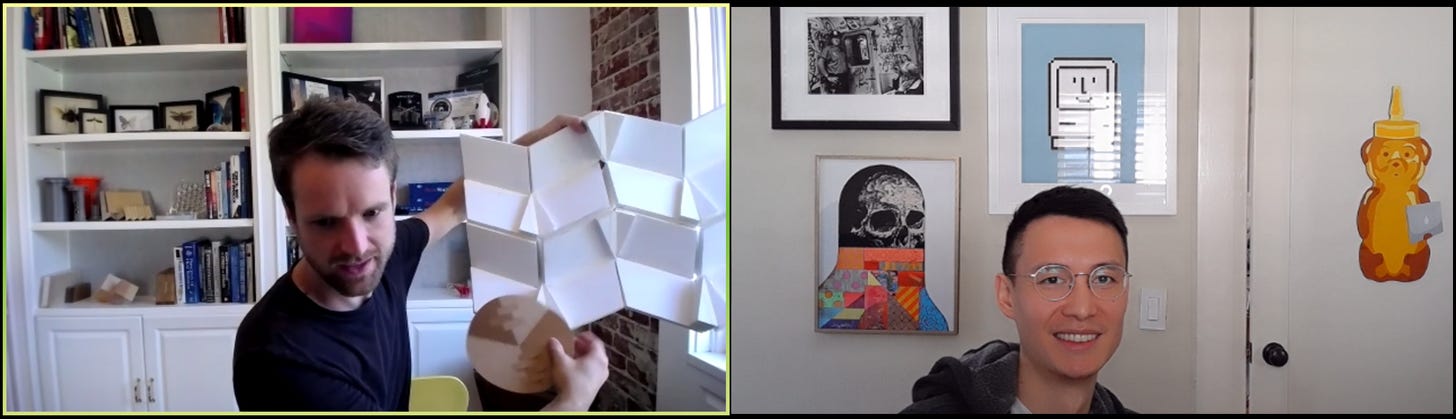

This week I had a chance to talk with Brian Ignaut—formerly the lead solar array designer at SpaceX—about his woodworking, his origami research, and the surprising ways it all relates to powering spacecraft. 🚀

The Most Popular Post this week was Shane Wighton’s brave haircut robot. As always, the entire week’s breakdown is below the interview.

I’m always looking for interesting people to interview, have anyone in mind?

- Kane

Interview with Brian Ignaut

You’re a leading expert in solar array design and in origami; which came first?

Solar array engineering was definitely the catalyst for my interest in origami. I could talk to a wall about solar technology if you put me in a room. I never was really into origami outside a few paper footballs, but I wanted to understand the physics-based asymptotes of how I could fold solar arrays into spacecraft, and Origami Engineering is one of the major fields of study.

I became the solar array lead at SpaceX because of my experience with new technologies. My previous work had been in utility-scale terrestrial applications with unique technologies. SpaceX was trying to explore new technologies and I was strolling into a field with a half century of expertise and prior art.

Was that intimidating?

It was actually empowering—in both terrestrial and space solar applications there’s a huge body of work and brilliant people. It’s like walking into a mine and seeing a huge vein of gold.

What exactly is the role of a solar array lead for a space company?

My team was responsible for the combined array systems and exploring multiple asymptotes: electronic performance, mechanical performance, etc, to understand where we could get the most performance per dollar of research.

The spacecraft only cares about watts (power), kilograms (mass), cubic meters (volume), kilogram square meters (inertia for steering), and hertz of the arrays (affects inertia for steering).

My goal is to maximize watts while minimizing mass, volume, inertia, and cost.

What’s different about designing solar for space compared to designing for terrestrial use that people probably don’t appreciate?

Space solar arrays are extremely limited by mass and volume. The fundamental physics of the arrays are the same.

Take the ISS (International Space Station) for example: the mass of arrays is ⅓ photovoltaics, ⅓ structure, ⅓ ascent protection. Only a third of the entire mass of the array is used for generating power.

The ascent protection is because launches are incredibly violent, both from the acceleration but also from the vibrations. Imagine peanut brittle the thickness of paper in a paint can on a paint shaker. That’s launching space solar arrays: the array team makes the peanut brittle, the vehicle team makes the paint can, the rocket team makes the paint shaker.

That sounds really stressful, what’s the dynamic between teams?

It sucks for everyone, everyone’s in the paint shaker. You have isotropic distribution of pain across the teams. It’s pretty collaborative. SpaceX was great because at a lot of other places, these teams are different companies. We could eat lunch together, exchange loads and margins and performance budgets more seamlessly. SpaceX has by far the most cost-effective technology in the space industry as a result.

Where did the origami come in? What *is* origami?

For SpaceX I needed to understand the history (what had been done), the competition (what was being done), and the field (what could be done). I was trying to understand the field of relevant research and bring in solutions from unexpected areas. Besides origami, entomology is a really good one—look at how bugs fold their wings.

Origami is the art of folding paper. Origami Engineering is describing how creases and their intersections can be used to generate mechanisms to solve real problems.

You have this basic problem of “I need to harvest a bunch of solar energy—I need a big area that fits in a small rocket”—people have been thinking about folding solar arrays a long time in the space industry, but even in biology and mathematics people are thinking about folding: proteins, bug wings, origami engineering—they all do research on how you can use folding math.

Origami Engineering let me explain in fundamental terms why certain solar array designs were better than others.

Also, I was always jealous of my software friends who could cheaply experiment at home. I had serious prototyping envy. I really liked mechanism design but it’s really hard and expensive to prototype. Origami let me whip up a six-bar mechanism utilizing two joined spherical four-bar mechanisms with shared links and zero backlash in sixty seconds [editor’s note: Brian demonstrated this for me while he was talking–I’ll take his word for it]. I can CRANK through prototypes of solar array mechanisms with Origami!

Who does this kind of research?

BYU has a compliant mechanisms lab, Erik Demaine was the youngest professor at MIT and specializes in mathematical folding, Tomohiro Tachi at The University of Tokyo has developed a lot of the more fundamental numerical approaches to folding, and Robert Lang, ex-Caltech. Lang and Tachi are the leaders in the field. The paper I published was with Lang and BYU.

You also build furniture on the side using origami techniques, and it’s gone viral on Reddit and Instagram a few times. What was the inspiration for starting Degrees of Freedom?

I always wanted to build beautiful mechanical things that people could enjoy. Things that people could interact with. I would always make people small mechanical presents. It also helped me compensate for the stress of working at SpaceX.

What’s your favorite product that you’ve made?

My favorite is the Kinetic Desk Lamp: it’s a monster technically. It’s three different mechanisms that are all linked so they move together. There are two different operational states that move between the singularity point. When’s it’s deploying it’s an over-constrained six-bar mechanism; when it’s actuating is a spherical four-bar mechanism. When it folds, there’s a point when four different rotational axis intersects and it transforms.

What about the best selling?

The things that people ask for the most are the ring box and the chess set. I proposed to my wife using the ring box. She loved it. I had desk toys and bugs on my desk for a long time for inspiration. This one toy, a month before I was going to propose, I finally figured out how to turn this mechanism into a nice box. We were in a race to propose first and I was afraid I wouldn’t solve the box in time. She already knew what ring I was getting so her reaction to the proposal was “holy shit, the box!” She forgot to say “yes” so I had to remind her.

It’s hard to make well! When the tolerances aren’t totally nailed it gets all loosey-goosey. When it’s right you can open it beautifully with one hand. I’ve connected with people all over the world that like it for different reasons: someone reached out to me for a box because they only had one hand, and they would be able to open the box and propose with this.

The mechanism that became the chessboard started out as me exploring a way to make a table that could easily change sizes:

How can people start down the rabbit hole of origami?

The biggest thing is just fold a Miura-ori tessellation - it’s the gateway drug. Miura is a professor at University of Tokyo. It’s the simplest single degree of freedom tessellation and it's simple and mesmerizing. Twists, Tilings and Tessellations is the great book if you want to go deep.

Any cool projects you’re exploring now?

So many of them. Other versions of the box project. A music stand for a friend. A stationary box for my sister.

What’s your favorite simple (or not so simple) tool that you think is under-appreciated?

This is super lame but the tool I love the most is the tape measure. It’s a beautiful demonstration of the parallel-axis theorem that tells you how area contributes to stiffness the further you are from the center. Any tape measure.

The Week in Review

July 31, 2020: Herbert Arnold 71/8.10 glass tube cracking-off machine.

I’d never stopped to wonder how they cut glass tubes down to length, but now I know! Funnily enough, the most active discussions I found about these machines came from the bong design community.

Manufacturer: Arnold Gruppe

July 30, 2020: Using a hose to clear morning dew off a putting green.

It’s worth appreciating that often, the simple solutions are the best. No fancy machines needed.

Manufacturer: Unknown

July 29, 2020: Haircut robot by Shane Wighton of Stuff Made Here.

Shane also made the basketball hoop that doesn’t let you miss. Fantastic hacker with a sense of humor. Shane’s day job is at Formlabs, whose 3D SLA printers we use at the office on our own various projects.

Manufacturer: Stuff Made Here

July 28, 2020: FarmBot Genesis CNC farming machine.

Open-source micro agriculture robot, what’s not to like? I am curious to see how these fare after a few summer showers though - ruggedizing machines to stay outdoors is non-trivial.

Manufacturer: FarmBot

July 27, 2020: North American F-82 Twin Mustang at EAA AirVenture Oshkosh filmed by Internal Combustion Channel.

This weird-ass conjoined plane was my favorite post of the week, but you all liked the haircut robot much much more. Believe it or not Twin Mustangs actually saw service during the Korean War. It’s fascinating to see the last throes of technologies in their twilight eras, shortly before being surpassed by a disruptive new technology (in this case, piston-engines to jets).

Manufacturer: North American Aviation

If you enjoyed this newsletter, forward it to friends (or interesting enemies). I am always looking to connect with interesting people and learn about interesting machines—reach out!

- Kane