MachinePix Weekly #34: Kyle Wiens, founder of iFixit

Kyle Wiens talks about open sourcing hardware, why repair is critical to civilization, and all the ways lawyers hate him. This week's most popular post was a special pastry machine 🍩

This week’s interview features Kyle Wiens, the founder of iFixit, advocate for Right to Repair, and a general pain-in-the-ass to corporate lawyers.

For 18 years, iFixit has been “open sourcing other people’s hardware” and publishing repair manuals for anything they can get their hands on.

The most popular post this week was a berliner (Berliner Pfannkuchen is a German doughnut with no central hole) injection machine. Identifying the make of this machine was one of my proudest @machinepix moments—this took some serious Google-fu.

I’m always looking for interesting people to interview, have anyone in mind?

—Kane

Interview with Kyle Wiens

I’ve read that the original iFixit teardown was an Apple G3; what happened that prompted you to document it?

It was an iBook G3. So my first job I was making $6.50 an hour at an Apple authorized service center. I worked a couple years in high school and saved enough to buy a G3, which was like $850. That was my computer to go to college with. Anyways I dropped it in my dorm room, pre-MagSafe, so I busted the solder joint in the charger port. I knew it was just a mechanical repair, so I figured it would be a simple repair. My grandfather had given me a soldering iron to send me off to engineering school, but ironically I was studying computer science so I only used the soldering iron for this!

I was trying to fix my iBook—and this is the issue with most of these laptops—there are a ton of screws, and I didn’t know the right way to untangle and route the cables. I also couldn’t find a service manual, which wasn’t public. I suffered through the whole thing. I remember taking it apart, going to bed at like 3 am, waking up looking at this pile of parts and thinking “what have I done?” I broke some tabs on the way, and the computer was never the same again. But now I knew how to take it apart. So publishing a guide was a little bit of a protest that Apple wasn’t making manuals available. I did some research later and realized Apple had issued DMCA takedowns to anyone that’d posted the service manual.

That’s what we do: we open source other people’s hardware. That’s what we did for them, or to them depending on how you look at it. We wanted an open culture, despite Apple's attempts at secrecy.

Which guides have been the most popular for iFixit?

Usually it's the new iPhone every year, that’s kind of the Super Bowl of teardowns for us. That said, the form factors haven’t changed that much recently. 6 to 6S, to 7 to 8. When the X came out that was very exciting, since it was a generational change. We’ve disassembled every major VR headset since the Oculus kickstarter. Watching that evolve has been really interesting.

Didn’t the Oculus team leave you an Easter Egg on their hardware?

We saw it online! They posted a picture of it, but we didn't see it in the wild. It must have been pre-production. If anyone knows how to buy one, let me know! Palmer Lucky chastised me on Twitter once or twice that we didn't take it apart completely! Well it was ultrasonically welded, and we didn't want to break it.

There’s always a balance: get the new thing, tell the story as fast as possible. Tell the story of the engineers. There’s a bit of a moral burden and time crunch now, people want to see the analysis the same day it comes out. We have to do the best job we can.

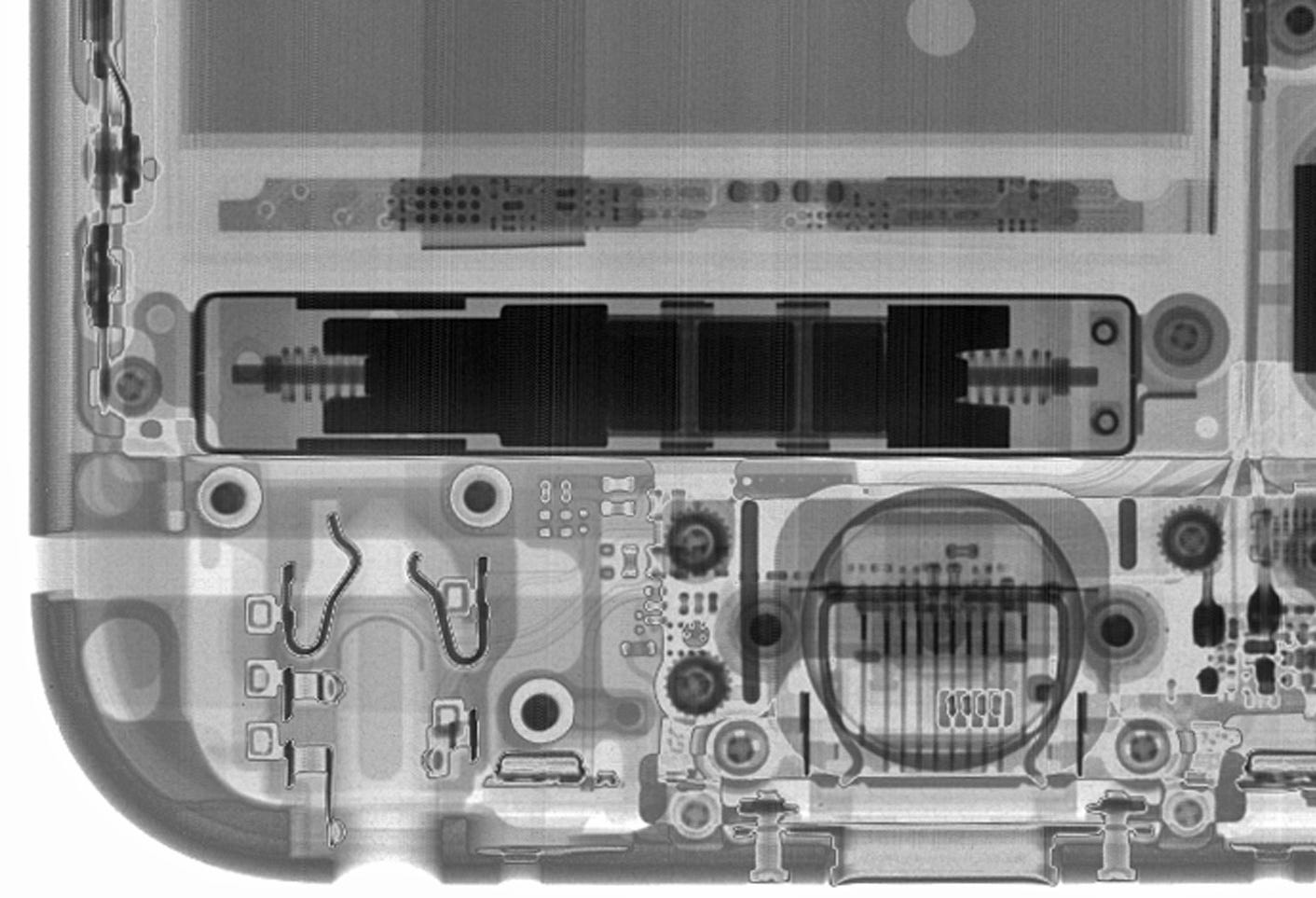

Do you use any hyper-spectral techniques to accelerate your understanding of new products?

We do a lot of x-rays now, occasionally we’ll do an MRI. We have an x-ray that records video! Like the Apple Taptic Engine vibrating, we got to see that with the x-ray video. Apple makes the best vibrators.

If you had to pick one product as an example of excellent design for repairability, what would it be?

Well, there’s a lot of products out there are designed to be serviceable. Like a bicycle: highly modular, off the shelf components.

For electronics, a desktop PC is the definition of serviceable. Most products we interact with in the world are perfectly repairable. It’s only on the bleeding edge of technology that serviceability becomes hard.

Yea I just got a new Mazda, my first car in over a decade, and it’s amazing how much more “black box” the engineering seems to be.

Yea, open the hood, pull all the plastics off and toss them. Mercedes at one point removed the dipstick from their engine, you had to use the sensors to check the oil. It drove people crazy! They put it back.

Software complexity feels free, but it’s really not. I have an old truck, big mechanical springs. I just went in and bent it back into shape. Imagine if I had to do that in code. Trying to get into the ECU. We could, if we could access it. Do we have the tools? The compiler? It’s so complex. This is the reaction all the farmers are having to the John Deere controversy. Ok fine, make things more complex, but give us the tools to work with them.

The problem came alight when I applied for an exemption to work on the software on my tractor with the Copyright Office, Deere lawyers said absolutely not, because if farmers could access the software on their tractors they would pirate Taylor Swift on their tractors. What?

What’s been the most frustrating product to tear down?

That’s a good question. The product we are most pissed off at is the AirPods. I think they’re the embodiment of things wrong in the world today. People ask me if planned obsolescence is real, and I generally say no, I don't think there's a secret back room with people planning failure—but the Apple AirPods, the failure modes are pretty bad. I think removing the headphone jack and selling a product that fails in 18 months is pretty bad. That’s the product I’m most salty about.

There are things that are hard to take apart. The Microsoft Surface is really thin and hard to take apart. The first Essential phone, we could not get the phone to open with heat, so we tried cold and it worked. The whole Essential community was kind of pissed at us, they told us it should open with heat, and we told them “guys, we tried a lot [of heat]”—maybe it was an earlier version with too much adhesive or something.

What trends have you noticed in product design over the past 18 years?

Lots and lots more adhesives. Double sided tape. If you look at how many types of tape are in an iPad - I don’t know all the kinds, but I’ve heard like 30. There are a lot of sub assemblies we don’t deal with, like mesh grilles etc. But if you’re a manufacturer you have to deal with all of that tape. We took the Apple Watch to a master watchmaker who’s worked on modifying and repairing Rolexes for years, and he just laughed at it. Poor workmanship. Obviously there’s differences in making millions of something, but there was a lot of tape in the Apple Watch. But it’s a totally different intent: Apple watch for years of use, a Rolex for decades.

This is a bit frustrating. On one hand, Apple has developed a bunch of hyper-precision processes, on the other they’re not using it to expand the lifespan of their devices.

That’s funny, one of our other interviews was with Chrissy, the first EPM on the Apple watch, and she mentions she loves double sided tape.

Absolutely! It works. I make furniture for fun, and sometimes when you need to make something, adhesive just works. It’s a short term band aid. If you’re making products that are designed to last for two or three years, you can get away with it.

I think some of that is changing. I have an Ikea desk—the Lisabo—and they found a way to make low cost joinery that will last for a long time.

Yea, Ikea gets a bad rap for their early particle board stuff, but their new stuff has been great. One trend that’s good for the environment is we used to have an iPod, and a camera, and a phone. Consolidating those things has been a reduction in mass. E-waste is still a huge problem, but we’re reducing total mass.

If we count the increased upgrade frequency of devices, do we still net out reduced mass?

It’s plateaued. Americans used to upgrade phones every 18 mos, now it's about 30 mos. We have a page on iFixit, we go through every couple years and update the stats.

Why is repairability important? How can people get involved?

Yea, I mean this is about resilience—about a society where we are not completely dependent on the manufacturing supply chain. When the pandemic started, supply chains froze, we had to look sound and say “what do I have right now, this is what i have to work with.” To have a sustainable electronic ecosystem, we need checks and balances between repairability and manufacturers.

Farms tend to be pretty resilient places: a lot of things are repairable, you can borrow parts, improvise parts. If we think about our technological life, it’s not really like that.

If you think about civilization, we’re scrambling as fast as we can up the mountain of technological progress. We’re hanging on by our hands—the more resilience we have, that’s supports, ropes, safety systems we’re adding. So if TSMC has to shut down a factory, we don’t fall.

Also, electronics manufacturing is one of the most polluting and wasteful industries we have. Right before COVID, I did this thing with Vice about the trade war tariffs, and we wondered if we could make an iPhone all in one place. We took an iPhone and mapped out all the places parts came from. If you just look at the processor, it’s based on an ARM Design in the UK, modified by Apple teams in Israel and US, using Korean memory, fabbed in Taiwan. Just that one part! It’s a global ecosystem. It’s fragile. You take one of those pieces away and we have a problem. I look at increasing access to repair as increasing the overall resiliency of the system.

There’s a meta argument between us and the manufacturers, we’re trying to introduce the right to repair, and they’re trying to stop it. It’s a fight over control. I’m here saying there’s the real world and entropy: you already sold the product, you don’t control it any more.

What’s iFixit and Apple’s relationship?

Apple has kind of an approach where they pretend we don’t exist. What you see in their environmental filings is a softening: they’re trying to reuse phones, etc. For a long time their stance was anti-repair, but it’s softening now.

We’d love to collaborate. They make wonderful products, we think there are places they could do better. We think Samsungs headphone designs are better. Apple’s phones are designed better.

We know Apple’s design teams use our tools: we know that because they’ve released videos and we can see them in the videos. I was in a legislative meeting the other week for Right to Repair, we’re on one side arguing for a solid legal foundation to repair, Apple says it’s fine there’s no problem.

I’m reminded of my old X220 which allowed easy access to every part of the laptop.

I’m concerned about some of the security strategies of the Apple M1 fundamentally changing the definition of what a personal computer is. You can’t boot M1 off an external drive, for example.

We work with a national lab, and they can’t send Macs out for repair because the data has to stay on the facility—but macs have their storage soldered onto the motherboard!

I remember a big April Fools joke where iFixit announced it was acquired by Apple.

That was a lot of fun. In the press release I said there wasn’t a number where we would capitulate, but it turns out everyone has a number.

We fooled CNN, they ran that story as a fact. I remember seeing that at 3 AM and having to reach out to the reporting and saying “hey man, this isn't real”.

We had two reactions from the Apple prank: employees at Apple called us and asked if they could still buy tools from us. Another is our servers got slammed with every spider and bot crawling us because people thought Apple would take down the archives.

That was fun. Apple has never offered to buy us.

Are you working on any side projects these days?

I planted an orchard this week. “Orchard” is optimistic. I planted 10 trees. I don’t know at what point it turns from a bunch of trees into an orchard. What else? We have a tractor hacking project to reverse engineer John Deere’s proprietary software: https://tractorhacking.github.io

I’m trying to get laws passed to institutionalize Right to Repair. We’ve had to open source people’s hardware for them - but really I’d like to build resources on top of official documents.

There was a while ago, when MacBook wireless cards were still discrete, it could fit back in upside down. If you did this it would fry the motherboard. This was only indicated in some secret manual somewhere. We had to update our documents to call this out. I wish we could have included that officially from the beginning.

Any favorite books or books you’re reading right now?

All time favorite book is Cryptonomicon by Neal Stephenson. Although the Baroque cycle is also amazing. I read a lot, this is kind of a fun one: The Innovation Delusion, this just came out. These guys run a group called The Maintainers. This whole book they’re saying “hey, is new fundamentally better? What’s our plan, what's our plan to make things last longer?” One example is our highway system. Amazing in the 50s, all decaying now. What’s our plan for making things maintainable? Our tax system and loads on the roads are not compatible.

What’s your favorite simple (or not so simple) tool or hack that you think is under-appreciated?

So many! I’m learning, there’s this cowboy I work with to do my fencing, when he’s using an acetylene torch, he’ll use that to light his cigarette.

We work with repair cafes, one guy says “I live a life of affordable luxury”. He just buys 10 year old stuff that nobody wants (Editor’s note: Laura Kampf also discusses the joy of working with scrap in her interview). If you want a boat, you can buy an old one for like $1000. I have 4 jet skis, I have less than $1000 in them. They’re really fun! That’s the lifehack. People are generally so wasteful you can just ride on the coattails. Another hack: buy popular things because there’s more information on how to work on them. There are real benefits to scale.

The Week in Review

Cosmic Perspective provided some amazing slo-mo footage of the unfortunate rapid unscheduled disassembly of SN10 shortly after it landed successfully for the first time.

The technique of candling for assessing eggs has been around for a long time, as evidenced by its name. As many astute readers pointed out, you can also automatically sort eggs from a candling table.

Concrete compaction removes bubbles from freshly packed concrete, increasing its density and strength. The process exploits an interesting material phenomena called liquefaction.

Postscript

It’s International Women’s Day and I’d like thank my mother, an aerospace engineer who taught me to be skeptical, challenge assumptions, and always measure twice. Love you mom.

If you enjoyed this newsletter, forward it to friends (or interesting enemies). I am always looking to connect with interesting people and learn about interesting machines—reach out.

—Kane