MachinePix Weekly #38: Shyam Srinivasan, senior hardware engineer, Snap

Shyam Srinivasan talks about the existential challenges of shipping consumer electronics. This week's most popular post was a snow tractor.

This week’s interview features Shyam Srinivasan, currently the CEO of Zitara Technologies, and previously a hardware engineer that shipped products for Snap, Casper, Nest, and Apple.

Zitara builds battery management software for performance monitoring, warranty management, and precise safety shutdown for companies with large battery deployments. His technology runs on some amazing EV and satellites fleets which his NDAs prevents him from talking about (although I tried) 🥲

The most popular post this week was a screw-propelled snow tractor. Fountainhead Antique Auto Museum claims to have the only operational unit, so it’s cool that they use it. As many people pointed out, the Snow Motor is a converted Fordson tractor, which itself was manufactured by Ford Motor Company.

I’m always looking for interesting people to interview, have anyone in mind?

—Kane

Interview with Shyam Srinivasan

You’ve worked as a hardware engineer on the electrical side for some top Silicon Valley companies. What initially brought you to EE?

You know, I was really interested in biomedical devices coming into college. I wanted to work on Brain-Machine interfaces. I thought it was the coolest thing, and electrical engineering is the place to go for that. You go from everything on how to read signals and do sensing, to fabricating MEMS sensors, to building computers and power systems to make it all work. On the other end, electrical engineering is where all the controls and statistics and math was developed for modern machine learning. Electrical engineering is the place to go if you want to understand how complex technologies really work from the silicon all the way up to the software and algorithms.

I also wanted a medical degree at the time, but what set me down this career path was doing really poorly at Caltech’s notorious 8 AM organic chemistry quizzes. Junior year, it was clear I wasn’t getting into medical school, so I was fortunate to be able to take some time off and explore what a career in electrical engineering would be. One of my TA’s in embedded systems programming introduced me to a co-op at Apple on the iPod team, where I met Chrissy! It was incredible at Apple. It combined my interest in music with understanding what mass manufacturing products actually looked like.

If you want to understand how everything around you works, you should start with electrical engineering. Electrical engineers have to touch the physical hardware and make it all fit, and support the software that’s going to run.

What do you think most people don’t appreciate about designing consumer electronics?

This is something that an early mentor of mine from Apple taught me: when you're building experiences for people, the hardest thing is being honest about what you’ve created and how it actually performs in the field. For engineers, that speaks to how we quantify user experience, how we measure it, how we actually validate it at scale and confirm that we’ve actually delivered those experiences. This is taken for granted in software, but takes a ton of hard work and honesty with hardware. That’s something people don’t appreciate. We want to iterate fast in hardware but it’s really really hard to know how your products are being used.

Is that because it’s just hard to collect real feedback about device usage?

The level of data required to know if you’ve truly enabled a creative experience for the customer requires mass production quality hardware. You need a lot of data points in the world, and even then actually measuring is nigh impossible.

A classical example is battery life for a customer. You know, on the design side we’re trying to predict the behavior of the battery and the user, both of which are really really difficult to model. What ends up happening in the field, customers don’t necessarily do what you expect them to, but they also don’t always complain—this makes understanding really hard. Your device might still be doing a great thing, and if something breaks in the hardware, the customer may work around it themselves. This may just cause the user to slowly lose trust in the device or not use it in certain ways. If I don’t trust my device has a good battery life, I may not just bring it with me. But that's a very different experience than what we tried to design. How do we collect that feedback? How do I measure that as an engineer? These problems are often invisible.

Another example is [bluetooth or wifi] pairing. A shocking number of devices are left unfinished by software engineers who assume they can OTA (Over The Air update) based on feedback. You go through all this effort to make this upgradeable device, but then 60% of users don’t ever connect it to the internet. You have to wonder if people are using it at all. The complexity, the root cause here: why don’t people do this thing you’ve assumed is simple? How do you find that answer?

What are some the craziest stories you can share about your time at Apple, Nest, Snap, Casper?

I think it’s incredible to see what has shipped that you never believed was possible. For me, some of the most unbelievable stuff I got to work on was at Snap. I helped out on Spectacles 1 and 2. It was really difficult to believe we could fit a battery, wifi radio, camera, full-on system-on-a-chip running Linux processor, and a little LED display in a pair of sunglasses in the amount of time that we did it. What is the craziest story around that? That it happened at all. You start to realize the real power of having shipped something of that complexity all the way out from design through creating a supply chain with precision that didn't exist before, designing novel power and thermal architectures—and seeing what happened over two, three years. You always overestimate what's happening in two, three years, and underestimate what happens in seven. Once you go out and solve some of those seemingly impossible challenges, you have a base from which to go attack even crazier things.

I think one thing that people take for granted is if you get hardware out there that's capable of sensing and actuating, like a thermostat, people assume everything falls into place. With wearables, the things that always go wrong are power and sensor noise. Software engineers kind of assume you can OTA it, and you don't need to solve it to ship - but you never know what’s going to go wrong until you’ve validated in the lab end-to-end and looked at data back from the field!

For the second-gen Nest Thermostat, a key feature was it could sense when you walked by and would wake the screen and learn your schedule. As is classic for new hardware, the software for this to work didn't arrive until very late in the process of mass manufacturing. We turn on the software, and found that every time we turned on the wifi radio, it appeared that someone was walking by the devices. Not only would it be turning on at random, it would sense people that weren’t there, and devices would just die on the wall from battery draw. We would have caught this sooner if we had a chance to test an integrated version earlier. I was blown away: in a week we designed and qualified a fix in both hardware and software. It was a miracle. The scale of it is hard to communicate, being in the factory, realizing you might have to open every box you’d already packed and add two very very small capacitors. But this was the difference between being able to revenue your first production units or not.

I will say that prior to networked thinking, being able to debug a problem that subtle would've been way more difficult. We used to have to grab logs from devices physically.

OTA sounds like a bit of a moral hazard. You can do a lot more, but also feel like you can get away with a lot more.

Yea! The joke in the industry is you can ship a brick as long as it has OTA. This may not actually be true.

What is the hardest thing you’ve had to do as an EE?

I think battery design. We designed a custom battery for Snap Spectacles, and that was the first time I got that deep into qualifying batteries and how they perform. One really interesting thing about wearables is that because of their relative size, you end up demanding really high discharge rates from batteries, much like people are trying to solve for EVs.

This is something I’m learning through Zitara: with consumer electronics warranties, in order to make a one year warranty, we just didn't have to understand batteries that well. We just had to bound it and make sure we didn’t get too many returns. Once people start tackling more challenging uses, and as consumer electronics try to do more with less mass and space, the complexity of the power system is going to be the limit of what you can do.

The power system is the limit of how much ML you can run on the edge, how much data can be passed around, literally everything you do is constrained by power. And batteries are the key mysterious piece we didn’t really have to solve before.

What is your personal favorite consumer electronic device? From an EE’s perspective, what do you think represents the craft of electrical engineering well.

Can I be really tacky and say the Nest Learning Thermostat? What was so incredible for me was that right out the gate we were impacting consumer behavior in a meaningful way. Because of the connectivity we built, we were selling services to the energy companies from day one. Not many people realize, selling the ability to timeshift the use of energy was a huge deal. Our success was measured in killing natural gas peaker plants. To me this was a transcendent experience. To create consumer demand for solving an industrial problem, through well-designed electronics, was the transcendent experience.

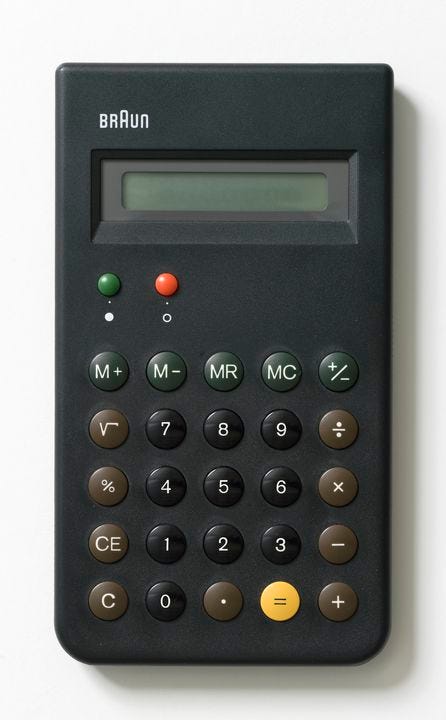

The canonical answer is the Braun calculator. It was a commitment to simplicity and design at a time when such a thing would have been nightmarishly difficult. I don’t know if there’s an analog today.

How do you think electronics will improve in the next 10 years? What should we expect as consumers?

The biggest change will be whatever kills the phone. Unclear to me what the actual technology will be, but what I do see coming is some magical leaps forward coming in batteries and battery algorithms over the next decade. That's going to enable more connected devices, more compute, more sensing, and more ML for everything from consumer/medical devices all the way out to rural cellular towers and LEO internet satellites.

Are you working on any side projects these days?

Oh, I’m really into gardening! We have like a system of hanging planters we’re building off of our balcony. We’ve been really into growing our own food.

Any favorite books or books you’re reading right now?

I’m listening to a very relevant book. It’s called Internal Combustion by Edwin Black. It’s all about the conspiracy driven by big auto and oil in collaboration with the US government to bolster addiction to cars and oil we’ve developed. To a great extent it has to do with single family zoning which generated the demand of having one car per adult.

That sounds like a depressing book.

Here’s why it’s not. People are worried that to make EVs happen we’ll need trillions of dollars of subsidy. To me, this book represents good news in a way: we did it before! It may sound like a depressing book because it talks about how consumption can be swayed, but my takeaway is if we can be swayed in the right direction we can do great things.

What’s your favorite simple (or not so simple) tool or hack that you think is under-appreciated?

Emailing people to ask them questions or ask them for things. If there’s one life-changing hack, people are really friendly if you ask good questions.

The Week in Review

I found a bunch of great diagrams of how this works on a Purdue Engineering website.

These have been manufactured as Erickson Air-Cranes since 1992, but since this particular unit tail number N793HT was manufactured in 1967, it’s a Tarhe.

An incredible bit of drama that had the entire world on the edge of its seat! Anchor handling tugs are used to tow and secure oil rigs, but also respond to emergencies such as the grounding of the Ever Given.

Postscript

GE has a 747 for testing its engines. Its GE9X is the largest commercial jet engine, absolutely dwarfing the other engines on the test aircraft 👇

If you enjoyed this newsletter, forward it to friends (or interesting enemies). I am always looking to connect with interesting people and learn about interesting machines—reach out.

—Kane